Due to COVID physical distancing we are unable to host conservation interns at this time. I thought I would continue looking into the way-back machine to share the work of previous interns. Most conservation programs require students to fulfill a placement with an established conservator mentor as part of their curriculum.

In 2006, a student attending the conservation program at Fleming College, Peterborough, Ontario, spent three months working on a variety of objects. One of the projects was to be used as a final research paper. The shoes selected for this purpose were purchased in 1984 from an antiques clothing dealer based in Switzerland. The condition of these silk satin shoes, on their arrival, was poor but the fact that they had the remains of a 1790 British maker’s label made them special. Plus, the fabulous yellow colour would be a unique additional to the BSM collection.

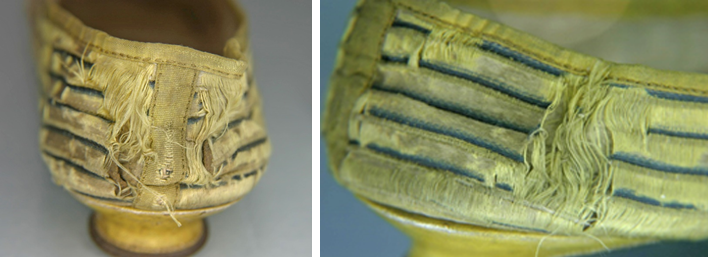

The float yarns, in the high stress areas, had disintegrated leaving the weft fibres hanging loose and the leather lining exposed. When weaving satin, the weft fibres run horizontally over three or four vertical warp fibres creating a smooth, shiny, reflective surface.

As you can see from the four photographs above, the parts of a shoe that experience the greatest wear are on the sides of the vamps, the ends of the toes and the heels. There is also considerable damage to the quarter, or side panel, of one of the shoes.

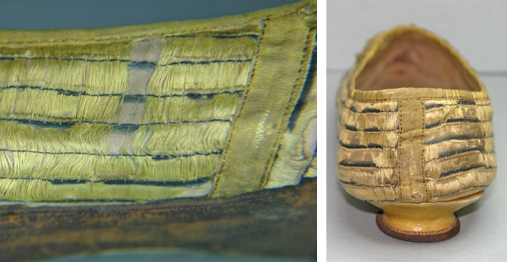

The first part of the project was to research how the shoes were made and the materials used. Next the intern reviewed past textile treatments to consider their options and consulted with the museum’s curator and the conservation mentor to determine the best course of action. Once this part of the process was finalized, adhesives were tested and suitable fabric replacements were dyed. Templates were made by securing polyethylene film over the area of loss with rare earth magnets, then tracing onto the film the perimeter of the loss. Fills were cut slightly larger than the loss to extend under the extant fabric and slipped between the satin upper and the leather lining. After adjustments, the fill was held in place with temporary stitches to prevent movement while work progressed. The loose weft yarns were passively humidified to align, then couch stitched to the new satin. In areas of significant loss, the striped pattern was mimicked on the fill with pencil crayons before stitching began.

The final steps were humidifying the creases in the vamps, reshaping the distorted counters (the heel area) and straightening the crumpled ruching (the pleated ribbon decoration) around the tops of the vamps. The end result is quite dramatic and far more photogenic!