The first Collections Management blog in this series walked you through the process of a new acquisition coming into the museum and discussed how much care we take in the shipping, receiving and unpacking of new acquisitions. Now that the item is in the building and it is being tracked through its registration number, the way it is handled and cared for takes a big turn. In the museum, the priority is to elongate the lifespan of all items in our care. We do this in several ways at this early stage. There are many important considerations when a new item is being processed in the registration area.

A recent donation received from shoe designer extraordinaire Benoît Méléard shown on the receiving table in the registration room, each item with its registration hang tag in place.

A recent donation received from shoe designer extraordinaire Benoît Méléard shown on the receiving table in the registration room, each item with its registration hang tag in place.

The workspace and equipment in the registration area are specialized for the tasks. The workspace allows enough room for the receiving, registering, examining, cataloguing, photographing and storing of new items as they move through the registration process. When objects are moved through one function to the next, a trolley is the preferred method of transport. It provides a stable and supportive surface to rest the object on, and a smooth mode of transport for the short journeys. Using the trolley reduces the probability of damage and accidents that can happen with carrying.

The person handling the object, the registrar, needs to plan ahead and think about how the object needs to be supported while it is being moved. The movement plan needs to include clearing the path ahead of time so the trolley can move smoothly to the destination. Also, a space needs to be created at the destination location that is adequate in size and location for the object. This may sound like excessive planning for a move that could only involve a few metres distance, but it will ensure the object is safe and secure.

A portion of the Benoît Méléard collection on an artefact trolley, being moved to its short-term home in the registration room for processing.

A portion of the Benoît Méléard collection on an artefact trolley, being moved to its short-term home in the registration room for processing.

The materials used in the construction of museum equipment is important. The steel trolley shown here is painted with a powder-coated finish that is heat set, which seals the metal, and the paint itself will off-gas less because the heat application requires little or no solvent. Similar manufacturing processes are preferred for our shelving materials. Materials like wood, some metal alloys and rubber may corrode and release acids and other volatile gases (off-gas) into the air, and those can damage objects over the long term. Materials tested to be inert, pH neutral and non abrasive are used in handling objects.

A close-up of an empty shelf in the Registration Room showing its powder-coated finish. The shelf is padded with microfoam, which is a foam-extruded inert plastic that has been tested to be chemically stable over time.

All surfaces the objects touch is padded with a layer of archival-quality, closed-cell polyethylene foam. See the photo above for a close-up view. This padding is chemically stable, pH neutral and non-abrasive, important factors in deciding what to allow so close to the precious items. We use this material to cover all of our work surfaces, line shelving and as cushioning material when ever needed.

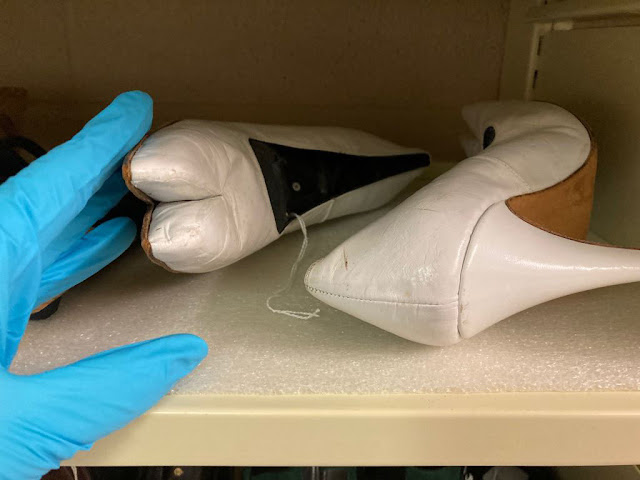

Protective nitrile gloves protect the objects from the salts and oils on hands, and protects the handler from substances on the objects.

Handling done by people is the most damaging thing that can happen to an object, so as soon as an item comes into the museum, it is handled only with gloved hands. Besides the potential for a person to break, drop or otherwise damage an object by holding it, the oils and salts on our fingers cause irreversible damage to the surface. As cleaning the object’s surface can cause the removal of its finish or worse, it is important to keep these oils and salts away in the first place. Now that the objects are in the museum’s care, they will not be touched with bare hands again.

The new Benoît Méléard donation resting on shelving in the registration room as it awaits the next steps of processing.

In the museum’s main floor gallery we have Behind the Scenes, an exhibition that gives visitors a sense of the spaces and equipment I’ve been talking about. The gallery has photographic panels showing shoes stored in the Museum’s vaults, and it features exhibition casework that is modelled on the actual trolleys that I’ve described above. You can see how similar in style they are in the image below, wheels and all.

Two ‘trolley’ exhibition cases featured in Behind the Scenes, on view at the museum now.

Two ‘trolley’ exhibition cases featured in Behind the Scenes, on view at the museum now.

Suzanne Petersen, Collections Manager