Guest Post, June 2012 By Samantha Conover

There are times when designers want plastic to look like plastic. In modern shapes with bold colours, high glosses and transparent elements plastics will proudly proclaim their synthetic nature. There are other times when designers seek to disguise plastic as a something else.

Through skillful manufacture, plastic can be made to look like many different natural materials. In the case of shoes, leather is the most desirable material for plastic to imitate. Faux leather is used primarily as a money saving measure, but is also prized for different physical properties (shine, durability) or because it is animal-friendly.

Early types of imitation leather were created by coating fabric with a mix of linseed oil and pigment and embossing it with a grained surface. In 1875 England, the original Leatherette was created for use in bookbinding. This material was similar to earlier imitation leathers, but used a thin layer of rubber instead of linseed oil.

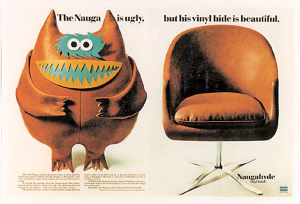

Modern methods of making imitation leather tend to follow the same basic formula of spreading a thin polymer layer over a fabric backing and embossing it with a grain. In the years after WWII, polyvinyl chloride (PVC) coated fabrics were developed. This material has good abrasion resistance but early versions tended to be stiff and un-breathable. The most famous PVC based faux leather is Naugahyde, invented by Uniroyal in the 1950s. Naugahyde is known for their surreal marketing campaign featuring the ugly-adorable Nauga, a mythical creature which happily sheds its vinyl skin for human use. As an aside, I realize this campaign must have inspired my dad who used to terrify my poor little sister with tales of the adorable fluffy Lycras that were killed so that she could wear her stretchy pants!

|

| Naugahyde ad “The mythical Nauga” |

| This Bata prototype from 1967 features a PVC based imitation leather paired with a molded PVC sole and heel. |

In 1964 DuPont introduced the world to Corfam with an enthusiastic song and dance number in their pavilion at the World’s Fair in New York. They claimed this miraculous new material was no mere imitation. Corfam was an improvement on nature and one more point of progress on the modern trend of manmade miracles! Corfam was the first “poromeric” material, a term used to describe a microporous and permeable material composed of a thin polyurethane layer over a fabric backing (in the case of Corfam, the backing was polyester). This new material was supposed to be breathable, comfortable, water-repellant and less expensive than leather.

Corfam was initially proclaimed a huge success after wear-tests by a sample of nursing staff. Unfortunately, it was later revealed that many negative responses were disregarded as “fit failure,” in other words; the nurses selected the wrong size shoes. In fact, these nurses simply chose a size that was slightly snug, expecting the shoe to stretch and conform to the foot like leather. This lack of pliability, along with high costs (Corfam ended up being more expensive than leather) and low breathability (complaints of terrible sweating and blisters were common) resulted in a consumer rejection of this miracle material. Later types poromeric polyurethane based faux leather were more successful , but some people are still wary of imitation leather.

| Corfam Ad from 1966 |

| “It’s that pleasure you’ll treasure when you wear Corfam shoes!” |

Plastics have also been used in order to give different effects to leather and synthetic materials. In the late 1800s a mixture of cellulose nitrate, pigment and castor oil over a textile backing was often used to create a patent leather effect. Modern patent leather effects are created by laying a thin layer of polyurethane over a leather base.

| “The shine of these sophisticated Givenchy patent shoes is achieved through the wonders of plastic” |

In the late 1960s a “wet look” or “crinkled patent” effect was achieve by the development of micrometer thin polyurethane coatings. This sexy, futuristic effect was a perfect compliment to mod style. Sadly, this look doesn’t last long. The thin coatings of polyurethane can become brittle with age which leads to crumbling and cracking

| “The wet look material of this Herbert Levine boot(above) is still sleek and sophisticated while the stresses from the embroidery have caused this Lady Diane boot(below) to crack” |

The quest for an inexpensive, comfortable and durable synthetic leather is still on. Most recent advances are in the development of micro-denier fibres which produce a more leather-like material. Interesting information about the development synthetic leathers and other uses for plastics in shoe manufactures can be found in this article from Satra, a leading research and technology center http://www.satra.co.uk/bulletin/article_view.php?id=297 .

Watch the video below from the 1964 DuPont World’s Fair video, which has the Corfam song in it!