Clothing and people come in all shapes and sizes. The challenge of displaying outfits for an exhibition is creating a form with the right proportions. Ten mannequins were required for the exhibition Art and Innovation: Traditional Arctic Footwear from the Bata Shoe Museum Collection; each one was dimensionally different but essentially used the same technique.

Fosshape® is a nonwoven polyester fabric that has a felt-like appearance and a low melting temperature. It has been used for years by the theatre community to make outfits and props. I chose the thicker of the two options as it would provide better support for some of the heavier clothing.

Two pieces of heavy weight Fosshape® were cut slightly larger than a preexisting foam mannequin which served as the base. They were hand sewn together with side and shoulder seams plus two darts on either side of the ‘spine’ to reduce excess bulk. A hot air gun, set at low, was passed over the surface of the Fosshape® causing it to shrink while taking on the shape of the foam form underneath. In order to remove the Fosshape® form, a long metal ruler was slipped up the spine between the fabric and the foam. A heavy duty utility knife was used to cut through the fabric, over the ruler, thus allowing the Fosshape® to be peeled away. Afterwards, the spine seam was hand sewn closed.

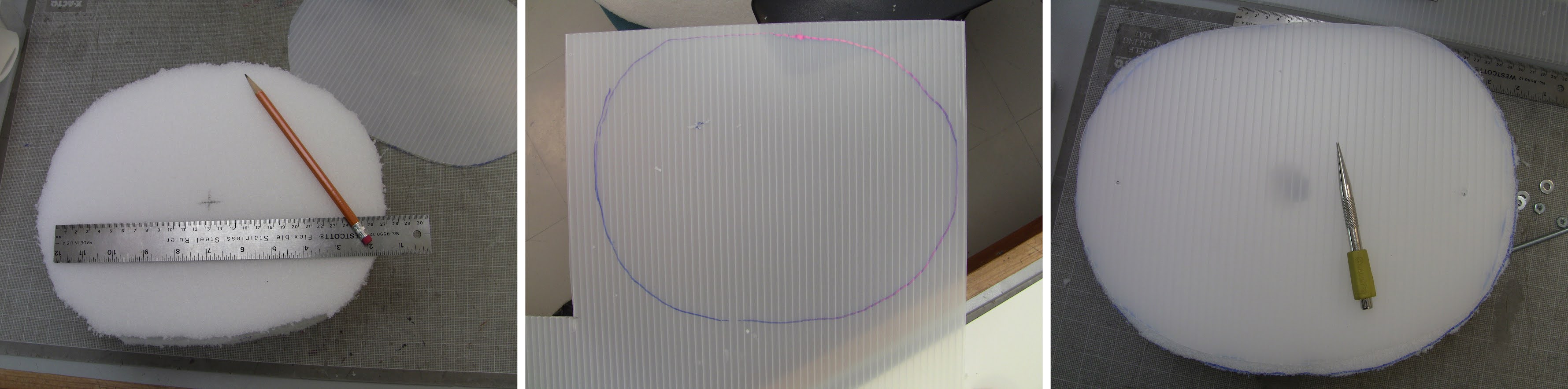

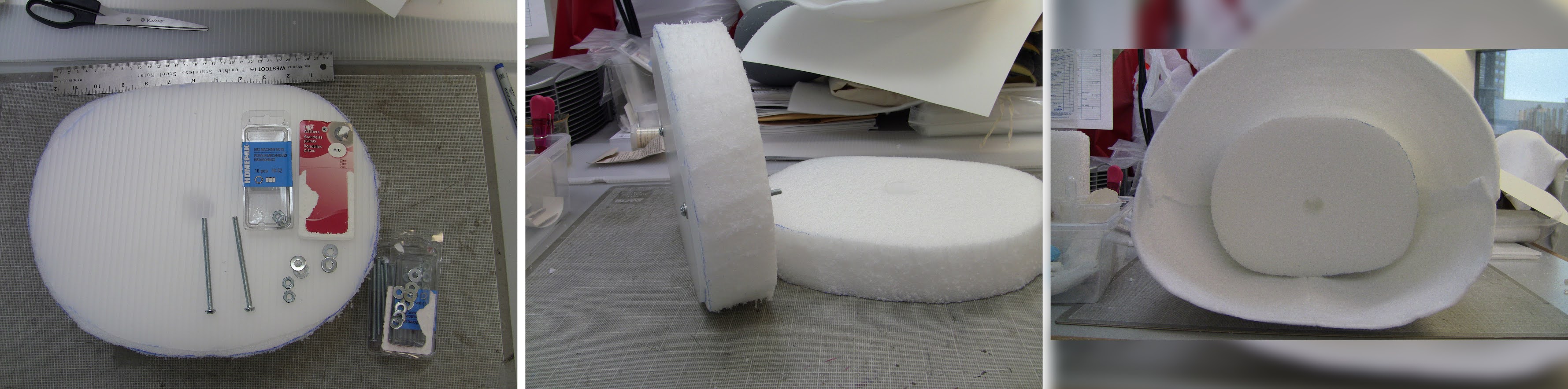

Internal foam supports were cut for the shoulders, waist, and hip areas to help distribute the weight of the garment. The exhibition designers decided the upright for each mannequin would be 1” thick acrylic rod attached to a square acrylic base. The internal foam discs needed to accommodate the acrylic rod. A 1” hole was bored out of the centre of the hip and waist discs. The top face of the waist disc was covered with a round of coroplast, a corrugated plastic, to provide a stop for the rod. The plastic sheet was secured to the waist disc with nuts and bolts, which gave the necessary resistance against the weight of the garment forcing itself down the acrylic rod. An awl was used to punch holes in the plastic through which the bolts were inserted.

All foam supports were attached to the interior of the Fosshape® foam with hot melt glue. Once the adhesive had dried, the acrylic rod was inserted through the hip disc and into the waist disc. The new mannequins were covered with a charcoal grey poly cotton stretch knit. For the Saami gentleman’s tunic and belt, we were able to refer to a photograph of the original owner wearing the outfit. There are eight coats in the exhibition – the two heaviest coats are displayed on solid foam mannequins and the remaining six are on Fosshape®.